Views: 0 Author: Site Editor Publish Time: 2025-12-18 Origin: Site

When planning a new facility or renovating an existing community, finding specialized healthcare furniture manufacturers for senior living is the most critical step for interior designers, facility developers, and project managers. Your furniture selections directly impact resident safety, comfort, operational efficiency, and your facility's long-term capital budget.

The senior living sector represents a $150+ billion market with significant annual growth, driven by demographic shifts, increased occupancy rates, and facility modernization investments. To secure the best value and comprehensive project support, smart buyers bypass generic commercial suppliers and partner directly with contract furniture manufacturers who specialize in the unique demands of Assisted Living, Memory Care, Nursing Homes, and Independent Living communities.

Founded on the principle of combining clinical functionality with contemporary design, Hongye Furniture has established itself as a trusted partner for healthcare facilities and senior living operators across the United States. For over 30 years, our focus has been on providing durable, code-compliant, and aesthetically pleasing healthcare furniture solutions that enhance resident dignity while supporting caregiver efficiency.

We pride ourselves on technical excellence, incorporating user-centric features like Wall-saver design and non-marring adjustable glides to protect both your facility's assets and your residents' well-being. Our contract furniture solutions are engineered to meet the rigorous demands of 24/7 use in healthcare environments, featuring robust construction and superior weight capacities of up to 250 kg (550 lbs).

Interlude Series - Award-winning modular seating for hospitals, clinics, and senior communities

Bariatric Furniture Solutions - Heavy-duty chairs and beds supporting diverse resident populations

Custom Design Partnerships - Collaborations with renowned designers like David Dahl

Healthcare Facility Installations - International Medical Center Hospitals and local senior communities

The senior living furniture market is experiencing unprecedented demand, with over 2,700 manufacturers providing specialized solutions in the United States alone. However, not all suppliers offer the same level of specialization, compliance expertise, and long-term partnership value.

Key Market Drivers:

Aging Population Growth - Adults 65+ population projected to reach 80+ million by 2040

Facility Expansion - Senior living communities growing at 10-12% annually

Regulatory Compliance - Stricter standards for safety, durability, and infection control

Design Modernization - Shift from institutional aesthetics to residential-inspired environments

Cost Optimization - Healthcare operators seeking better value through direct manufacturer relationships

The furniture required for senior living communities is not residential—it is highly specialized commercial-grade casework engineered for 24/7 use in demanding healthcare environments. Professional procurement teams search for manufacturers who meet strict compliance and durability requirements established by ANSI, BIFMA, and state/federal healthcare bodies.

| Standard | Scope | Application to Senior Living |

ANSI/BIFMA X5.1 | General-purpose office chairs | Lounge, dining, and administrative areas |

ANSI/BIFMA X5.4 | Lounge & public seating | Waiting areas, community spaces |

ANSI/BIFMA X5.11 | Large occupant seating | Bariatric-rated furniture (22"+ seat width) |

CAL TB 133 | Flammability standards | Upholstered furniture compliance |

ADA Accessibility | Accessibility requirements | Approach, transfer, and usage standards |

NFPA 260 | Flame testing for materials | Fire safety compliance |

ANSI/BIFMA G1 | Ergonomics guidelines | Dimensional comfort for diverse user populations |

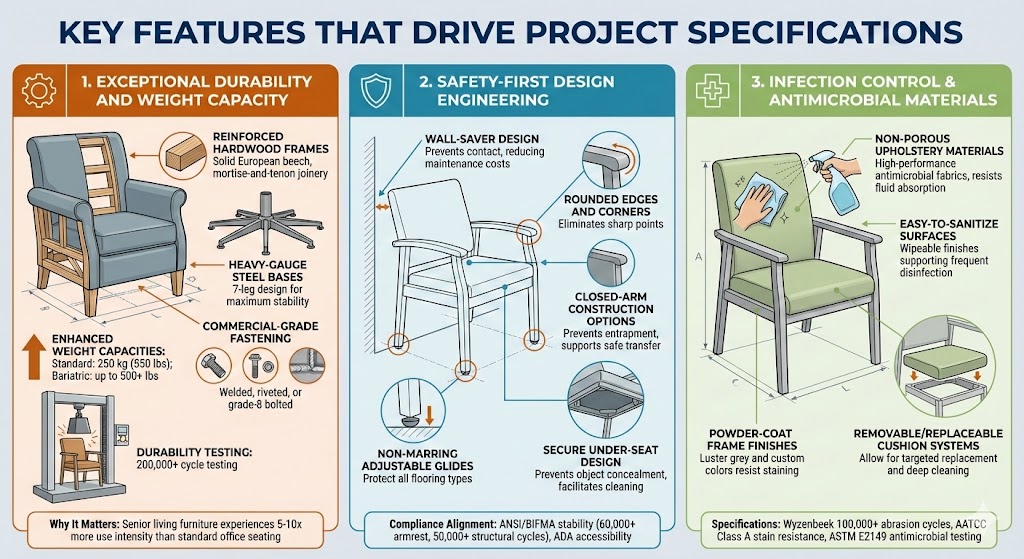

High-traffic environments demand furniture built for constant use, frequent cleaning, and diverse resident populations. Our seating is engineered with:

Reinforced hardwood frames - Solid European beech construction with mortise-and-tenon joinery

Heavy-gauge steel bases - 7-leg designs for maximum stability vs. standard 5-leg office models

Enhanced weight capacities - Standard: 250 kg (550 lbs); bariatric options: up to 500+ lbs

Commercial-grade fastening - Welded, riveted, or grade-8 bolted connections

Durability testing - 200,000+ cycle testing (vs. standard 100,000 for office furniture)

Why It Matters: Senior living furniture experiences 5-10x more use intensity than standard office seating, requiring structural engineering that prevents premature failure and costly replacement cycles.

Patient and resident safety is paramount. Our approach includes:

Wall-saver design - Back panel engineering prevents contact with walls, reducing maintenance costs and preserving facility aesthetics

Non-marring adjustable glides - Protect all flooring types (tile, laminate, wood, carpet) from scratching and wear

Rounded edges and corners - Eliminates sharp points that could cause injury during transfers or mobility support

Closed-arm construction options - Prevents entrapment and supports safe transfer mechanics

Secure under-seat design - Prevents object concealment and facilitates cleaning protocols

Compliance Alignment: Features align with ANSI/BIFMA stability testing (60,000+ armrest cycles, 50,000+ structural durability cycles) and ADA accessibility requirements.

Healthcare environments demand materials that support rigorous cleaning and disinfection protocols:

Non-porous upholstery materials - High-performance antimicrobial fabrics resisting fluid absorption

Easy-to-sanitize surfaces - Wipeable finishes supporting frequent disinfection cycles

Powder-coat frame finishes - Luster grey and custom colors resist staining and support cleaning protocols

Removable/replaceable cushion systems - Allow for targeted replacement and deep cleaning

Specifications: Wyzenbeek 100,000+ abrasion cycles, AATCC Class A stain resistance, ASTM E2149 antimicrobial testing

For large-scale senior living projects, partnering directly with specialized healthcare furniture manufacturers offers distinct advantages over working with general distributors or furniture retailers.

| Benefit | Direct Manufacturer Advantage | Value for Procurement Teams |

Superior Cost Efficiency | True wholesale pricing + volume discounts (15-30%) | Better budget control and ROI on furniture investment |

Customization & Design Flexibility | Ability to modify fabrics, finishes, dimensions, frame styles | Exact alignment with design vision and facility aesthetics |

Design Collaboration | Access to in-house design teams and specialized consultants | Custom solutions for unique architectural or operational needs |

Quality Assurance | Direct control over production, testing, and materials | Consistent quality and reliability across all installations |

Supply Chain Transparency | Direct communication with production facilities | Predictable timelines, real-time status updates, fewer delays |

Compliance Documentation | Certifications, test reports, and compliance evidence readily available | Streamlined approval processes and regulatory submissions |

Extended Support | Warranty, maintenance guidance, and long-term technical support | Reduced total cost of ownership over furniture lifespan |

Modular Solutions | Access to complete statement of line (single-seaters, two-seaters, three-seaters, dining options) | Cohesive design aesthetic across entire facility |

Project Impact: Direct manufacturer partnerships typically reduce procurement timelines by 25-40%, improve design consistency, and lower per-unit costs compared to distributor models.

Professional healthcare furniture manufacturers offer modular product families supporting diverse facility needs:

Core Seating Options:

Guest Chairs (closed-arm, open-arm variants) - Dining, lobbies, community areas

Bariatric Chairs (closed-arm, open-arm) - Heavy-duty support for all resident populations

Lounge Chairs - Common areas, waiting spaces, leisure environments

Loveseats - Two-person seating for family visits and community gatherings

Sofas - Three+ person seating for activity areas and gathering spaces

Specialized Solutions:

Sleepover Chairs - Family accommodation during extended visits

Dining Tables - Height-adjustable, accessible designs

High-Density Frames - European beech with mortise-and-tenon joinery

Customizable Features - Removable seat covers, solid-surface armcaps, optional wood finishes

| Specification | Standard Options | Healthcare Optimization |

Frame Material | European beech or steel | Hardwood for aesthetics + steel reinforcement for durability |

Upholstery | Performance fabrics, polyurethane leather | Antimicrobial, non-porous, 100,000+ Wyzenbeek cycles |

Armrest Options | Poly caps, solid-surface panels, wood veneers | European beech arm caps, reinforced with metal brackets |

Powder Coat Finishes | Luster grey, custom colors | Healthcare-grade finishes resistant to staining |

Cushioning | High-density foam, density-specific profiles | Pressure-relief options, removable covers for cleaning |

A: Our furniture is engineered to meet or exceed key industry standards for safety, durability, and accessibility, including:

ANSI/BIFMA X5.1 and X5.4 - For general-purpose and lounge seating

ANSI/BIFMA X5.11 - For large occupant (bariatric) seating

CAL TB 133 - California flammability standards (many facilities apply nationwide)

ADA Accessibility Standards - Approach, reach, and transfer requirements

State-specific healthcare regulations - Vary by jurisdiction; we maintain compliance databases for all 50 states

We provide comprehensive compliance documentation, third-party testing reports, and certifications to streamline your facility's regulatory submissions and inspections.

A: We specialize in customization while maintaining efficiency. While we offer a comprehensive standard catalog covering most facility needs, we frequently collaborate with design teams to:

Modify fabrics, finishes, and dimensions

Customize frame styles (open arm vs. closed arm configurations)

Create semi-custom or fully custom pieces for unique architectural constraints

Develop color-matched options aligning with facility design standards

Incorporate designer collaborations (similar to our partnership with renowned designer David Dahl)

Lead times for customization vary; please contact our sales team for project-specific timelines.

A: Lead times vary based on product customization, order volume, and current capacity. However, as a direct manufacturer, we offer significantly more transparency and control than distributor models:

Standard catalog items: 8-12 weeks typical

Customized specifications: 10-14 weeks (fabric/finish modifications)

Large volume projects: Negotiable with early coordination; some phased delivery available

Rush options: Premium expedited timelines available for time-critical projects

We recommend submitting RFQs (Request for Quotations) early in your project timeline to confirm delivery schedules. Our project coordinators provide real-time updates throughout the manufacturing and delivery process.

A: Hongye Furniture operates state-of-the-art production facilities featuring:

Vertical Integration - Direct control from raw material sourcing through final packaging

Quality Assurance Testing - In-house testing labs for ANSI/BIFMA compliance validation

Sustainable Manufacturing - Environmental certifications and responsible sourcing practices

Geographic Advantage - [Insert Location] headquarters enabling efficient distribution across [Region]

Artisan Craftsmanship - Combination of traditional joinery techniques with modern production precision

This ensures consistent quality, reliable timelines, and the ability to respond quickly to design modifications or urgent facility needs.

A: Our streamlined procurement process includes:

1. Initial Consultation - Schedule a call with our project coordinators to discuss facility needs, timeline, and budget parameters

2. Space Planning Assessment - Provide facility floor plans, occupancy projections, and specific area requirements (dining, lounges, corridors, bedrooms, etc.)

3. Product Specification - Our design team curates recommendations aligned with your facility aesthetic and compliance requirements

4. Quote Preparation - Detailed pricing, timeline, warranty, and support options

5. Value Engineering - Alternate options if budget adjustments needed

6. Contract Finalization - Clear terms, delivery schedules, and post-installation support

Request a Quote - Contact our sales team: +86 137 0227 9783 or hy@hysdfurniture.com, to download our Senior Living Furniture Catalog for standard specifications.

Selecting a partner for healthcare furniture for senior living is more than a purchasing decision—it's an investment in your facility's quality, safety, efficiency, and reputation. The right manufacturer brings:

Technical expertise aligned with industry standards and regulations

Design excellence balancing institutional requirements with residential comfort

Quality assurance ensuring durability and long-term value

Project support from initial planning through post-installation optimization

Partnership mindset committed to your facility's long-term success

Hongye brings over 30 years of experience, proven installations across healthcare and senior living sectors, and a commitment to combining clinical functionality with aesthetic excellence.

Your residents deserve furniture that supports their dignity, safety, and comfort. Your staff deserves solutions that enhance efficiency. Your facility deserves a partner who understands both.